MotorLab Facilities

The Missouri S&T Electric Machines and Drives Laboratory was established in 1984 by Emerson Corporation. The facility consists of 6 interconnected research stations each with a 15-kW 2700-RPM dynamometer and associated power sources and metering equipment. The laboratory is presently being upgraded with modern equipment based on a 2004 gift from Emerson.

Dynamometer Stations

Each dynamometer station consist of a 15-kW dc machine powered by a modern four-quadrant drive. The rated speed range is from -2700-RPM to 2700-RPM. A variety of test motors are available at each station including 3.7-kW induction, compound dc, and wound-rotor synchronous machines. The machines are mounted on a torque table which has the capability of sensing up to 20-Nm. Meter and contactor panels are available for connection of power sources and sensing instantaneous values for up to six voltage and six currents.

A typical dynamometer station.

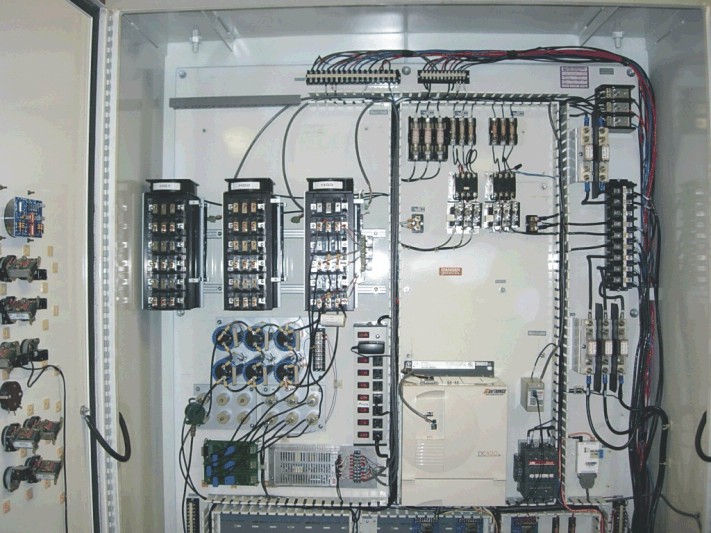

Each station is also fitted with the latest in power electronics and DSP/computer control. Specifically, three heat-sinks (each containing six IGBTs) are mounted inside the station cabinet and can be connected externally to the front panel for interfacing to the machinery. The IGBTs are driven externally through fiber connections by a TI TMS 320F2812 DSP.

Inside the station cabinet.

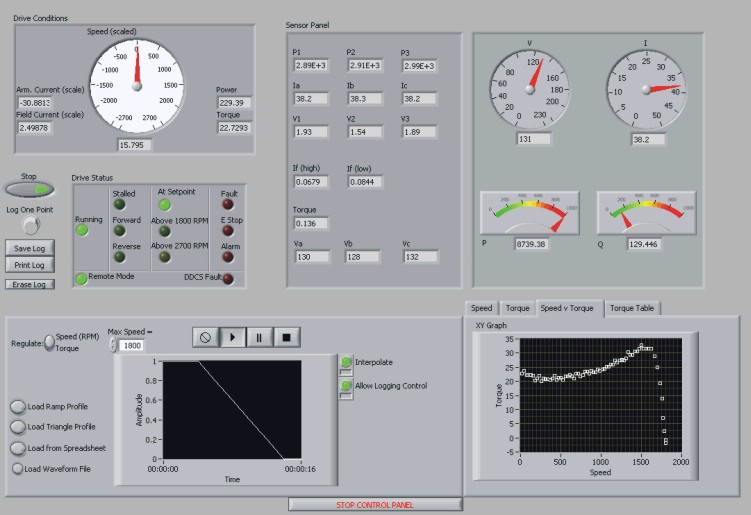

A recent update to the stations is a LabView interface to nearly all of the station components. From one screen, the dynamometer can be controlled, the voltage and current sensors can be read, the contactors can be switched, and commands can be sent to the DSP.

Computer, scope, and DSP.

Screen-shot of the LabView interface.

Power Electronic Racks

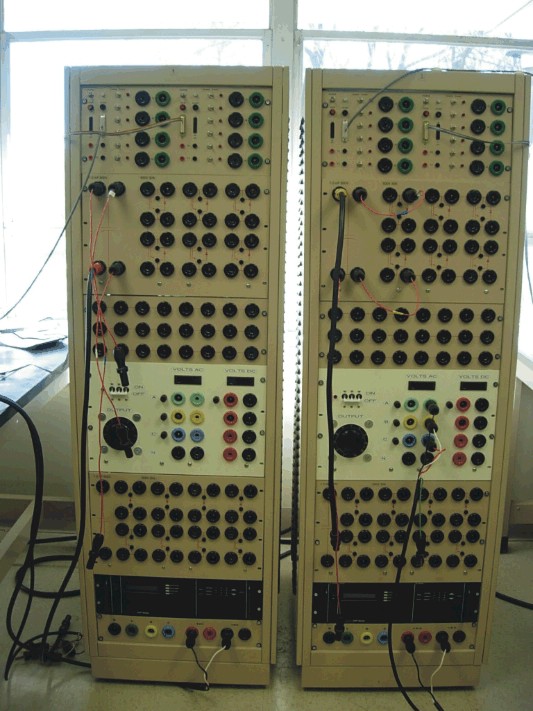

In addition to the power electronic components at each station, the MotorLab has two mobile power electronic racks. Each rack consist of thirty-six (36) IGBTs and associated fiber-driven gate drive circuitry. These units are self-contained in that the sensors, DSP, and computer control are on the back side so that no external connections are required. The control is located close enough to the power section to reduce interference, but on the other side of a wall for safety. On the power section, the IGBT configuration can be re-wired to make a wide variety of power converter topologies including multilevel and multi-phase structures.

Mobile power electronics rack.

Small Motors Lab

For studying small motors (less than 1-kW), four (4) stations have been set up. Each station consists of a motor/generator test stand, a PC with data acquisition card, a meter panel, a scope with current and voltage probes, and a rack of power sources and power electronics. For test motors, each station has the traditional synchronous, induction and dc machines as well as permanent-magnet ac machines for brushless dc drive experiments.

Small motor dynamometer station.

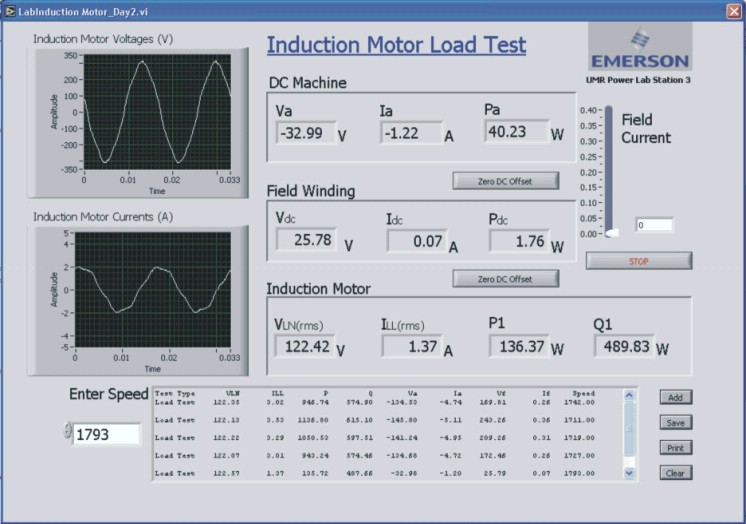

The meter panel contains six (6) channels of voltage and current sensors which are read by the PC. A LabView interface is used to display voltage and current waveforms as well as rms voltage, rms current, average real power, and average reactive power. The LabView interface has considerable capability and is frequently updated to include other functions such as power supply control.

Software interface for the induction machines experiment.

The power electronic racks were installed in 2002 based on a gift from Ameren UE. They are custom-built into a standard equipment rack and contain a controllable dc power supply, an ac-dc source panel, an inverter shelf, and a control and sensor interface. The power electronic components are configured for standard motor drive applications such as PWM dc drives and three-phase PWM ac drives. An external Microchip DsPIC microprocessor used to control the power electronics shelf.

Power electronics racks.

The Missouri S&T MotorLab is also equipped with various size Magtrol dynamometers for testing small motors (less than 4-kW). The largest of these is an HD-815-8 with a capability of up to 12,000-RPM and 28-Nm. The medium-sized Magtrol dynamometer is an HD-715-8 capable of operating at speeds of 25,000-RPM and torques of 6.2-Nm. The smallest is a model HD-500-8 with a capability of 20,000-RPM and 550-Nmm.

Magtrol dynamometers.